We learn to install a ladder in a private house with our own hands on our detailed instructions with photos and diagrams

We install a ladder in a private house with our ownThanks to the overall stable economic situation in the country, many families can now afford to have their own private home. Some of them are increasingly building them in several (at least two) floors. Naturally, without stairs, movement in such a structure will be difficult. With a seemingly simple appearance, the ladder design can not do without preliminary correct calculations and understanding by the master of the features of human walking. The reliability of the ladder, its functionality and aesthetic appearance can be severely affected by incorrect calculations or incorrectly selected material. This all needs to be given due attention. In principle, the stairs make the interior space of houses more elegant and complement the feeling of prosperity.  If you decide to take up the installation of stairswith your own hands, then you should have not only the skills of owning tools, but also a set of initial knowledge about the main components of the stairs and its varieties. The following information is especially useful to those who first decide to take up such work. Varieties of stairs of private houses. The modern variety of stairs and materials, from which they can be made, is extremely large. However, knowledge of their range is not enough, it is necessary to understand the design features of each and performance characteristics. Do not be afraid, it is better to be patient. Most owners of houses with several floors install basically 3 variants of stairs: on bolts, screw and usual marching. They are able to perform the role of walkways, interstorey, entrance or working stairs. At the same time, their construction is acceptable not only inside the house, but also outside. Glass, metal, artificial and natural stone, concrete or reinforced concrete, plastic, wood and combinations of them - this is an incomplete list of materials that are used in the manufacture of staircases. Determine the purpose of the ladder, the planned load on it, evaluate your material capabilities, study the merits and demerits of each species, and then you can make the right choice.

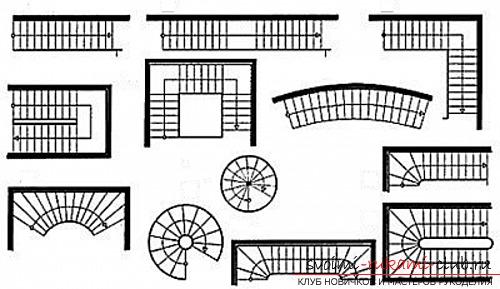

If you decide to take up the installation of stairswith your own hands, then you should have not only the skills of owning tools, but also a set of initial knowledge about the main components of the stairs and its varieties. The following information is especially useful to those who first decide to take up such work. Varieties of stairs of private houses. The modern variety of stairs and materials, from which they can be made, is extremely large. However, knowledge of their range is not enough, it is necessary to understand the design features of each and performance characteristics. Do not be afraid, it is better to be patient. Most owners of houses with several floors install basically 3 variants of stairs: on bolts, screw and usual marching. They are able to perform the role of walkways, interstorey, entrance or working stairs. At the same time, their construction is acceptable not only inside the house, but also outside. Glass, metal, artificial and natural stone, concrete or reinforced concrete, plastic, wood and combinations of them - this is an incomplete list of materials that are used in the manufacture of staircases. Determine the purpose of the ladder, the planned load on it, evaluate your material capabilities, study the merits and demerits of each species, and then you can make the right choice.  Option number 1. Spiral staircase.

Option number 1. Spiral staircase.  To this kind of ladders resort, mainly,when there is not enough space to install a conventional straight ladder, or when another type of construction is impossible. Certainly, such a ladder is less comfortable to use, but its main trump card in the other is saving space. As a rule, it is used for ligaments with basement floors or an attic. Screw staircases do not spoil the interior of the house at all, but on the contrary bring neat elegance and uniqueness. Screw stairs are often made of wood, plastic, metal and even stone, although the latter material is not only expensive, but also difficult to work with. Option number 2. The flight of stairs.

To this kind of ladders resort, mainly,when there is not enough space to install a conventional straight ladder, or when another type of construction is impossible. Certainly, such a ladder is less comfortable to use, but its main trump card in the other is saving space. As a rule, it is used for ligaments with basement floors or an attic. Screw staircases do not spoil the interior of the house at all, but on the contrary bring neat elegance and uniqueness. Screw stairs are often made of wood, plastic, metal and even stone, although the latter material is not only expensive, but also difficult to work with. Option number 2. The flight of stairs.  Definitely the most popular version of the performanceStairs: this distribution they have not only historically. Here an important role is played by the simplicity of manufacture and the presence of structural features that take into account human mechanics when walking. For such stairs, a much larger free area (usually more than three square meters) is required, which, naturally, can be classified as a disadvantage. Although with the equipment of the flight ladder, there is an opportunity to save space, which is facilitated by rotary march structures with interstorey platforms. The list of materials for the manufacture of such stairs, in principle, is the same as for screw equipment. It is only worth noting that the precedence here is held by concrete and wood. The first due to its economy and durability, and the second due to its ecological and traditional. Option number 3. Stairs on the mountains.

Definitely the most popular version of the performanceStairs: this distribution they have not only historically. Here an important role is played by the simplicity of manufacture and the presence of structural features that take into account human mechanics when walking. For such stairs, a much larger free area (usually more than three square meters) is required, which, naturally, can be classified as a disadvantage. Although with the equipment of the flight ladder, there is an opportunity to save space, which is facilitated by rotary march structures with interstorey platforms. The list of materials for the manufacture of such stairs, in principle, is the same as for screw equipment. It is only worth noting that the precedence here is held by concrete and wood. The first due to its economy and durability, and the second due to its ecological and traditional. Option number 3. Stairs on the mountains.  The name of this type of staircase was borrowed fromGerman, where the word "bolzen" means "bolt". Large bars, bolts or pins are screwed or embedded in one of the walls, and the steps are put on them. The indisputable advantage of staircases on the patients is their compactness and saving on materials. But on the other hand they are suitable only for stone houses with strong walls. The frame and handrails for the stairs on the bolts are made of metal, of course, and the steps are made directly glass, wooden, concrete or metal. With apparent brittleness, the ladder ladders are capable of withstanding solid loads. Elements of the stairs in the house. Like most designs, the ladder includes a number of elements that are made separately, and then are assembled with each other. Despite the fact that some staircase elements vary depending on its type, it is advisable to get acquainted with each of them. This is especially important in the design process.

The name of this type of staircase was borrowed fromGerman, where the word "bolzen" means "bolt". Large bars, bolts or pins are screwed or embedded in one of the walls, and the steps are put on them. The indisputable advantage of staircases on the patients is their compactness and saving on materials. But on the other hand they are suitable only for stone houses with strong walls. The frame and handrails for the stairs on the bolts are made of metal, of course, and the steps are made directly glass, wooden, concrete or metal. With apparent brittleness, the ladder ladders are capable of withstanding solid loads. Elements of the stairs in the house. Like most designs, the ladder includes a number of elements that are made separately, and then are assembled with each other. Despite the fact that some staircase elements vary depending on its type, it is advisable to get acquainted with each of them. This is especially important in the design process.  Steps. They also represent a composite element, consisting of a riser and tread. The horizontal surface on which your foot rests on the stairs, this is the tread. Its size is selected depending on the convenience of placing a step on it. Most experts are inclined to believe that the optimal width for the tear is 30 centimeters. Its length determines, in turn, the width of the future ladder. It is advisable not to go beyond 90-150 centimeters.

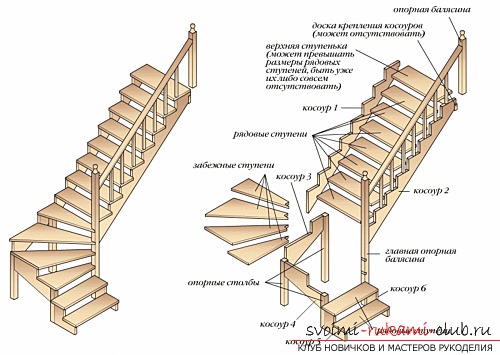

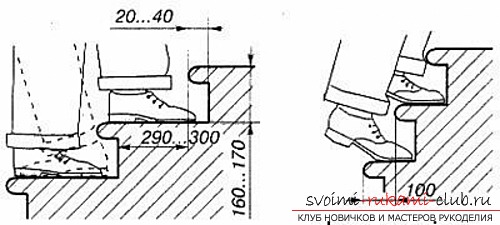

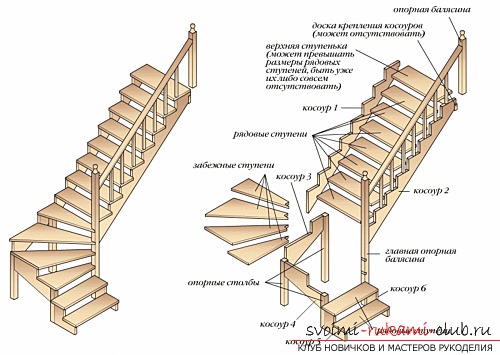

Steps. They also represent a composite element, consisting of a riser and tread. The horizontal surface on which your foot rests on the stairs, this is the tread. Its size is selected depending on the convenience of placing a step on it. Most experts are inclined to believe that the optimal width for the tear is 30 centimeters. Its length determines, in turn, the width of the future ladder. It is advisable not to go beyond 90-150 centimeters.  The vertical part, which connects two treads,called riser. In height, it is usually 15-20 centimeters. Some masters make stairs without riser to create an unusual design. Pay attention: in the spiral staircases the width of the two edges of the steps is different. The widest step, for example, can be 45 centimeters, with a central part width of about 25 centimeters. Support beams. It is quite logical that the stairs should be attached to something. For this purpose, support beams, existing 3 types: pillar, kosour, and bowstring are designed. The first of these is used for spiral staircases, and the second two for marching. The bowstring is a wooden beam with a thickness of more than 50 mm, in which the cuts are made from the inside for the tear. Unlike it, the Kosowor has triangular notches under the steps. Posts for the spiral staircase are usually made of stone, metal, concrete or wood. Railing. Their appointment is very important - ensuring safety while walking on the stairs. Railings are based on two main constructive elements - balusters and handrails. Support for handrails are balusters, which together serve as a guard for the stairs. There are times when you can fix the handrails on the wall. As a rule, the material for the handrail is selected according to the main material of the steps. In order not to get confused in terminology, you should understand that the march is a series of steps with rails, separated by staircases. Installation of stairs with your own hands. As the theater begins with a hanger, so the installation of the ladder begins with the project. It can be developed independently in one of the computer programs, or ordered from a specialized organization, where they will not only conduct all necessary calculations, but also perform the ladder drawing (of course, not free of charge). If you decide to design yourself, then you need to take into account a set of basic rules, features and requirements for designing different types of staircase structures. This refers to the location of their installation, the size and the level of slope. A place to install the stairs. The above-described parameters are significantly influenced by the equipment of the future staircase. For the right choice, you should know a few basic rules: - if the area planned for the staircase is less than three square meters, you can not do without a spiral staircase, in any other case you are free to choose between a bolt and a flight of stairs; - the most comfortable are found marching stairs, however, their length (more than 4 meters) can not all be allowed. In this case, it is necessary to make a turning marching staircase; - the ladder is impossible without the presence of a supporting structure into which its fastenings are screwed in or screwed. The size of the ladder.

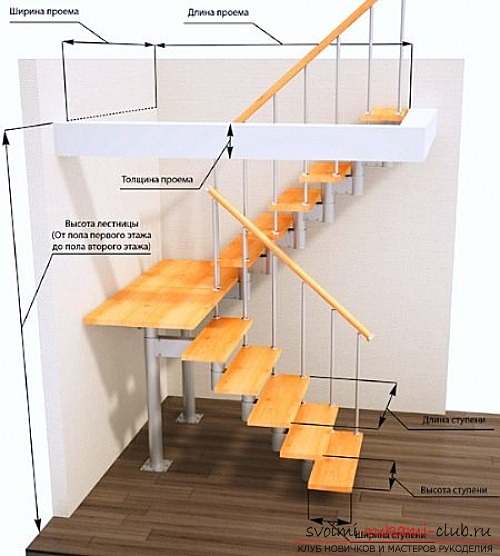

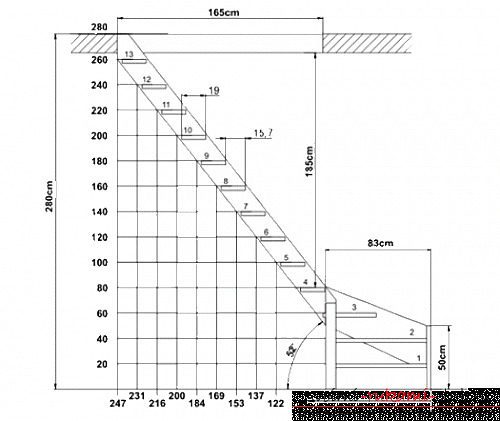

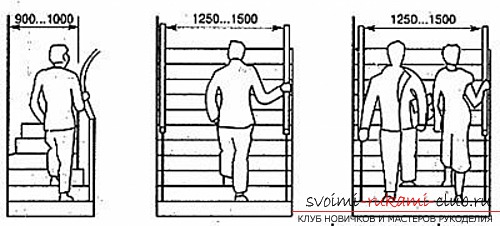

The vertical part, which connects two treads,called riser. In height, it is usually 15-20 centimeters. Some masters make stairs without riser to create an unusual design. Pay attention: in the spiral staircases the width of the two edges of the steps is different. The widest step, for example, can be 45 centimeters, with a central part width of about 25 centimeters. Support beams. It is quite logical that the stairs should be attached to something. For this purpose, support beams, existing 3 types: pillar, kosour, and bowstring are designed. The first of these is used for spiral staircases, and the second two for marching. The bowstring is a wooden beam with a thickness of more than 50 mm, in which the cuts are made from the inside for the tear. Unlike it, the Kosowor has triangular notches under the steps. Posts for the spiral staircase are usually made of stone, metal, concrete or wood. Railing. Their appointment is very important - ensuring safety while walking on the stairs. Railings are based on two main constructive elements - balusters and handrails. Support for handrails are balusters, which together serve as a guard for the stairs. There are times when you can fix the handrails on the wall. As a rule, the material for the handrail is selected according to the main material of the steps. In order not to get confused in terminology, you should understand that the march is a series of steps with rails, separated by staircases. Installation of stairs with your own hands. As the theater begins with a hanger, so the installation of the ladder begins with the project. It can be developed independently in one of the computer programs, or ordered from a specialized organization, where they will not only conduct all necessary calculations, but also perform the ladder drawing (of course, not free of charge). If you decide to design yourself, then you need to take into account a set of basic rules, features and requirements for designing different types of staircase structures. This refers to the location of their installation, the size and the level of slope. A place to install the stairs. The above-described parameters are significantly influenced by the equipment of the future staircase. For the right choice, you should know a few basic rules: - if the area planned for the staircase is less than three square meters, you can not do without a spiral staircase, in any other case you are free to choose between a bolt and a flight of stairs; - the most comfortable are found marching stairs, however, their length (more than 4 meters) can not all be allowed. In this case, it is necessary to make a turning marching staircase; - the ladder is impossible without the presence of a supporting structure into which its fastenings are screwed in or screwed. The size of the ladder.  The size of the future staircase is largelyonly the presence of the necessary space for it, but also the convenience of walking along it. For example, in a spiral staircase, the width, as a rule, is one meter. The same indicator in a mast or staircase stairs varies within the range of 1.2-1.5 meters, which is convenient for simultaneous movement of two people.

The size of the future staircase is largelyonly the presence of the necessary space for it, but also the convenience of walking along it. For example, in a spiral staircase, the width, as a rule, is one meter. The same indicator in a mast or staircase stairs varies within the range of 1.2-1.5 meters, which is convenient for simultaneous movement of two people.  Of course, the width of the spiral staircase can bemake and 1.5 meters, only this will entail an increase in the area that it will occupy. The sum of all the steps of the ladder, from the initial to the last, is the length of the ladder structure, while the staircase is also taken into account for the staircase.

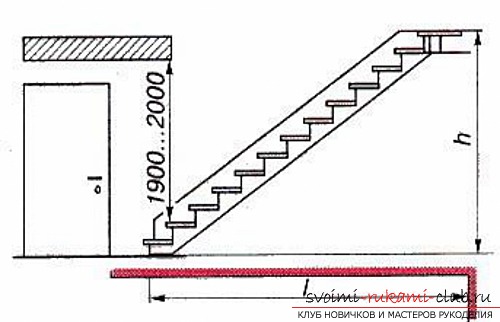

Of course, the width of the spiral staircase can bemake and 1.5 meters, only this will entail an increase in the area that it will occupy. The sum of all the steps of the ladder, from the initial to the last, is the length of the ladder structure, while the staircase is also taken into account for the staircase.  The height is even easier to define - it is identicalheight between floors (from floor to floor). The first step should be at the height of the riser, and the upper one at the floor level of the next floor. The angle of the stairs. Experts are inclined to consider as an ideal level of a slope of a ladder - 45 degrees. However, it is not always possible to achieve it. Often owners of houses are forced to construct stair structures at an angle of 55 degrees and even more, which, in turn, leads to a decrease in the convenience of walking along it.

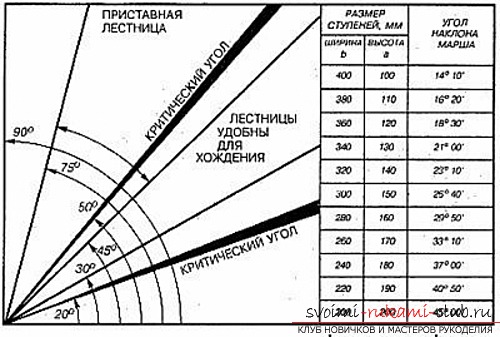

The height is even easier to define - it is identicalheight between floors (from floor to floor). The first step should be at the height of the riser, and the upper one at the floor level of the next floor. The angle of the stairs. Experts are inclined to consider as an ideal level of a slope of a ladder - 45 degrees. However, it is not always possible to achieve it. Often owners of houses are forced to construct stair structures at an angle of 55 degrees and even more, which, in turn, leads to a decrease in the convenience of walking along it.  Attention! All three dimensional parameters of the ladder: the slope angle, the width of the tread and the height of the riser with each other are interrelated. As the angle of inclination decreases, the width of the tread increases and the height of the riser decreases. As the angle increases, the tread decreases and the riser increases. In our table, according to the slope level, the dimensions of the riser, as well as treads, are indicated. According to the table you can see for yourself that the most comfortable are the stairs with an angle of 30-45 degrees. Installation of a spiral staircase.

Attention! All three dimensional parameters of the ladder: the slope angle, the width of the tread and the height of the riser with each other are interrelated. As the angle of inclination decreases, the width of the tread increases and the height of the riser decreases. As the angle increases, the tread decreases and the riser increases. In our table, according to the slope level, the dimensions of the riser, as well as treads, are indicated. According to the table you can see for yourself that the most comfortable are the stairs with an angle of 30-45 degrees. Installation of a spiral staircase.  The installation of this type of staircase is considered one of the most difficult, which is due to the fan arrangement of the steps. If you decide to build such a ladder, then follow the further instructions:

The installation of this type of staircase is considered one of the most difficult, which is due to the fan arrangement of the steps. If you decide to build such a ladder, then follow the further instructions:

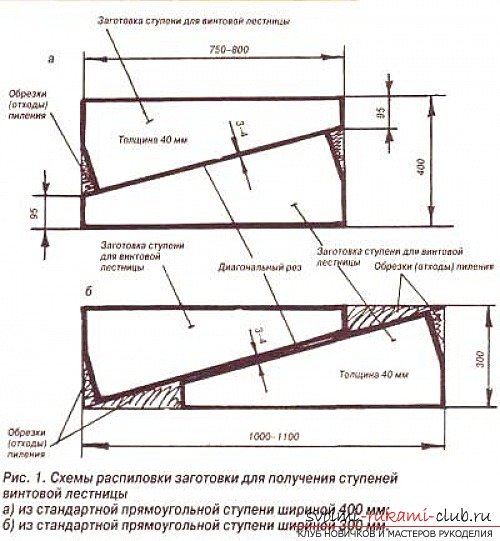

- start making steps. In case you plan to make a staircase wooden, take a wide board and mark it diagonally under one or two steps. Then cut it and process the edges. In the case of choosing a stone staircase, it will be processed in a special workshop. Stone can be replaced with concrete. To do this, we create a form of future steps, in which we lay reinforcing bars, fill cement mortar or concrete and expect final drying out;

- pre-made steps, produceinstallation of a vertical stand (support). In accordance with your project, it will be either integral or set-up. With the stacking rack, first mount the main support (pipe diameter of about 5 centimeters), which is put on the bushing and calcination of rubber. With a single stand, grooves are made in the places where the steps are fastened, and then the steps are laid;

- Now let's go directly to the installationsteps. Take pre-made blanks and put it on the pipe, pressing it with a wide bushing. Then extend the steps with a fan and connect them to each other with vertical brackets, for extra strength of our design. Or, as an option, fix them with the bolts to the wall. In the case of using an integral support, the steps are installed in the grooves, similarly connected by brackets and strengthened by the bolts;

- work is completed with the manufacture of handrails and theirinstallation. This stage can be considered one of the most difficult, because the balusters will have to be sharpened from solid pieces of material, and the handrails should be made arcuate.

Installation of a flight of stairs.  The manufacture of such a ladder, in comparison withscrew, it is easier, but you do not need to relax and you need to fully observe the correctness of the technology. Directly the editing will consist of the following stages:

The manufacture of such a ladder, in comparison withscrew, it is easier, but you do not need to relax and you need to fully observe the correctness of the technology. Directly the editing will consist of the following stages:

- First of all, we make risings and treads. Having marked out and sawing out the boards, we have to process their edges, providing them with smoothness and evenness;

- then begin to make the supporting beams - strings orKosower. To make the last of the tree you need to create a template that will look like a rectangle and fully correspond to the size of the step itself. We need to mark the parts for the cutout, attaching the resulting template to the beam. Then gently cut them out. To create a string, we have to mark the points under the grooves at certain intervals along the inside of the beam, into which we will later insert the treads. Slots should have the same angle of inclination as the ladder. Making a ladder of metal, for you the most acceptable is to weld the corners under the steps from the inside;

- completing the process of manufacturing support beams, weit is necessary to install them in place, firmly securing there. If you planned a platform on the stairs, then first install it, and only then the supporting beams;

- proceed to mount the steps. First install the riser and fix it, and then - tread. Self-tapping screws are suitable for fastening, which we will "flush" flush. In metal staircases, we put the tufts of wood on the corners and fix them with screws;

- After completing the installation of the steps, we begin the installation of balusters and handrails.

Thus, as you can see, making a ladder inA private house with their own hands is not a super complicated task. Naturally, today there is an opportunity to buy a ready-made staircase. Deciding to buy it, keep in mind that the price will start from one thousand cu, so it will be much more profitable to create a staircase with your own hands.