The design of warm slippers-boots allows you to sew custom home shoes yourself

The pattern of warm slippers-boots is not difficult.It can be built quite easily by every craftswoman who wants to sew warm and beautiful house shoes on her own. In this article you will find pictures and a description of how to construct a pattern that you can easily use in your work. In their appearance, house slippers-boots can resemble the long-known ugs. They are very soft and cozy. With them, your feet will always be warm. These slippers have many advantages. If you have already encountered sewing before, namely, sewing bags, various cases, mittens, then sewing them should not be difficult for you. You can sew such slippers-boots from anythinganything, from any available materials. Surely each of us has an old sheepskin coat, boots, sweaters, and jeans at home. These things will serve as the basis for the future product. In this case, it will cost you mere pennies. Now it's time to tell you about what slippers can be made from. Many different materials are used to sew such unusual house shoes. You can use shoe leather or leatherette as a sole. For insoles, split leather, suede are most often used, or you can take cloth. In the area where the insole and sole of the boot are located, there is a cushioning layer. It can be cut out of simple regular cardboard. This is the material that, perhaps, everyone has. Also, the padding can be padding polyester or foam rubber. In order for you to get durable slippers that will serve you faithfully for many years, you should always use only high-quality materials, in particular threads. Any cotton, cotton lavsan or lavsan will do. Well, in order to sew individual elements of the upper part of house boots, you can use ordinary nylon threads.

You can sew such slippers-boots from anythinganything, from any available materials. Surely each of us has an old sheepskin coat, boots, sweaters, and jeans at home. These things will serve as the basis for the future product. In this case, it will cost you mere pennies. Now it's time to tell you about what slippers can be made from. Many different materials are used to sew such unusual house shoes. You can use shoe leather or leatherette as a sole. For insoles, split leather, suede are most often used, or you can take cloth. In the area where the insole and sole of the boot are located, there is a cushioning layer. It can be cut out of simple regular cardboard. This is the material that, perhaps, everyone has. Also, the padding can be padding polyester or foam rubber. In order for you to get durable slippers that will serve you faithfully for many years, you should always use only high-quality materials, in particular threads. Any cotton, cotton lavsan or lavsan will do. Well, in order to sew individual elements of the upper part of house boots, you can use ordinary nylon threads. All cut edges, of course, if you haveIf this is possible, it should be done using a sewing machine. Well, try to stitch the top by hand. I recommend that you purchase an awl from a specialized store. It, in turn, will help you with sewing slippers, no matter how hard the material is. Using this tool, you can easily sew all the details.

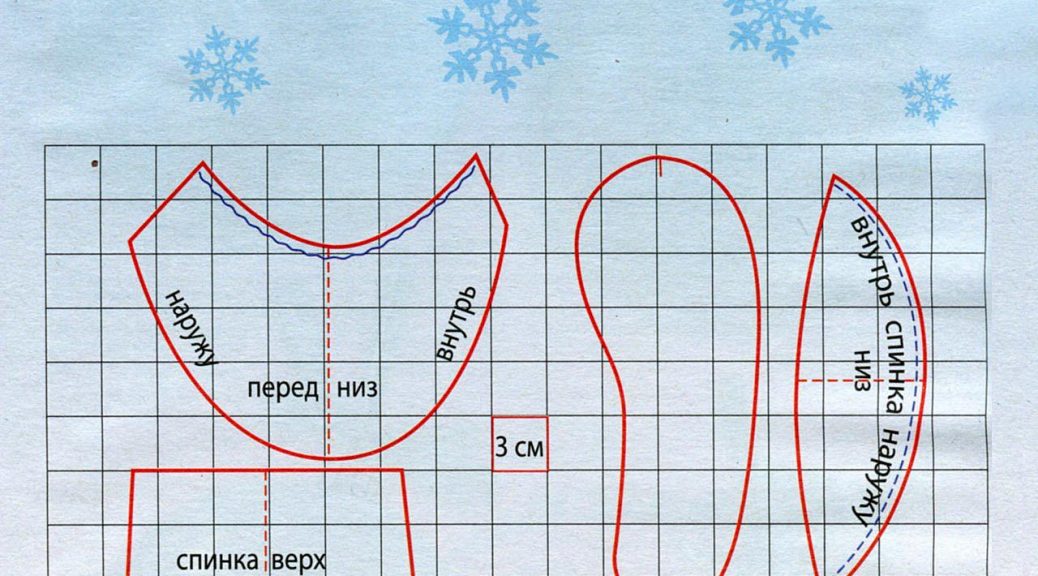

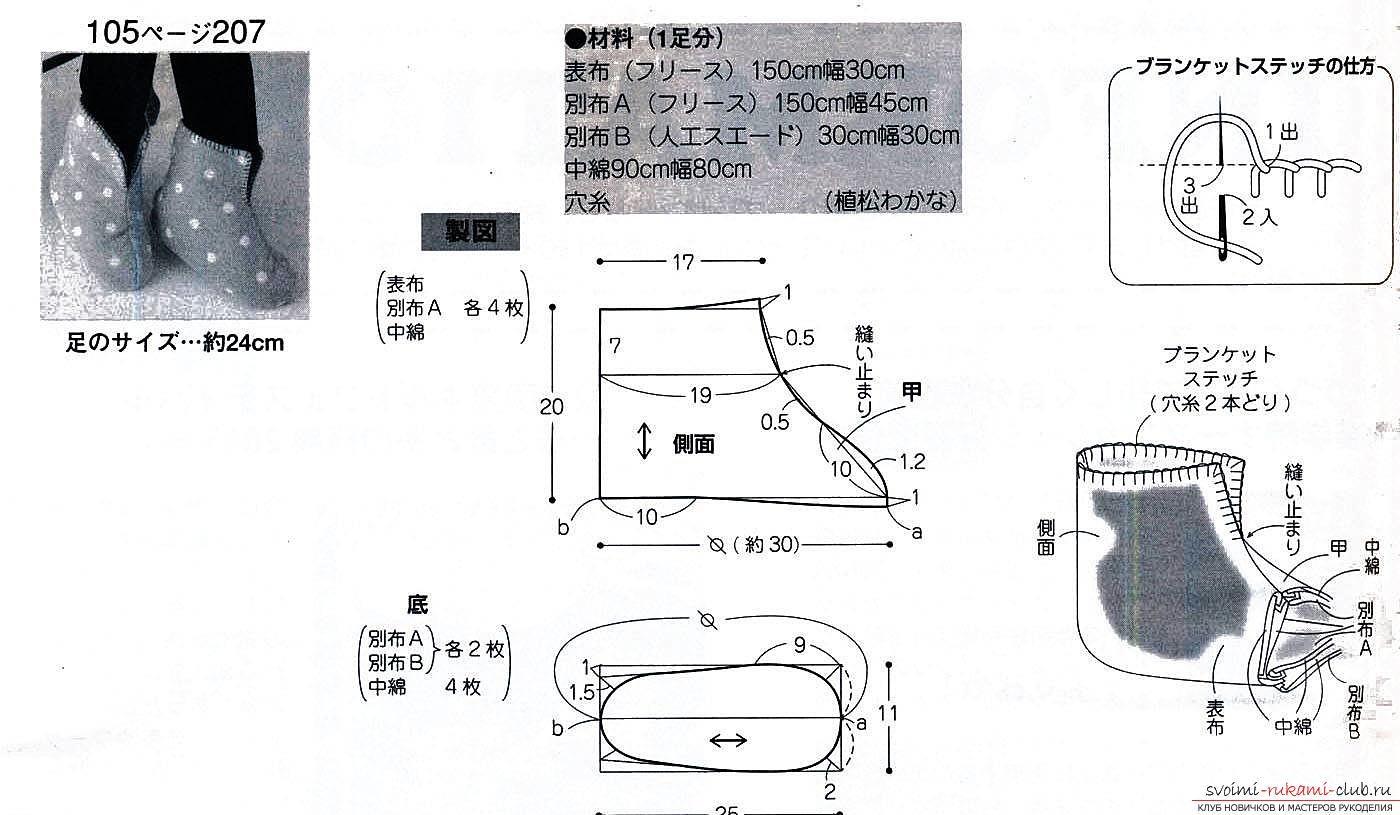

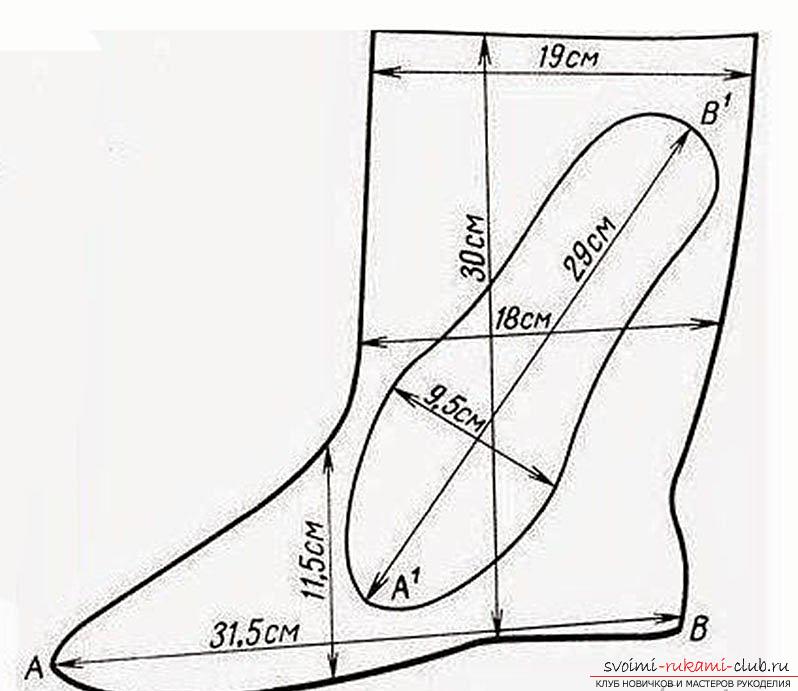

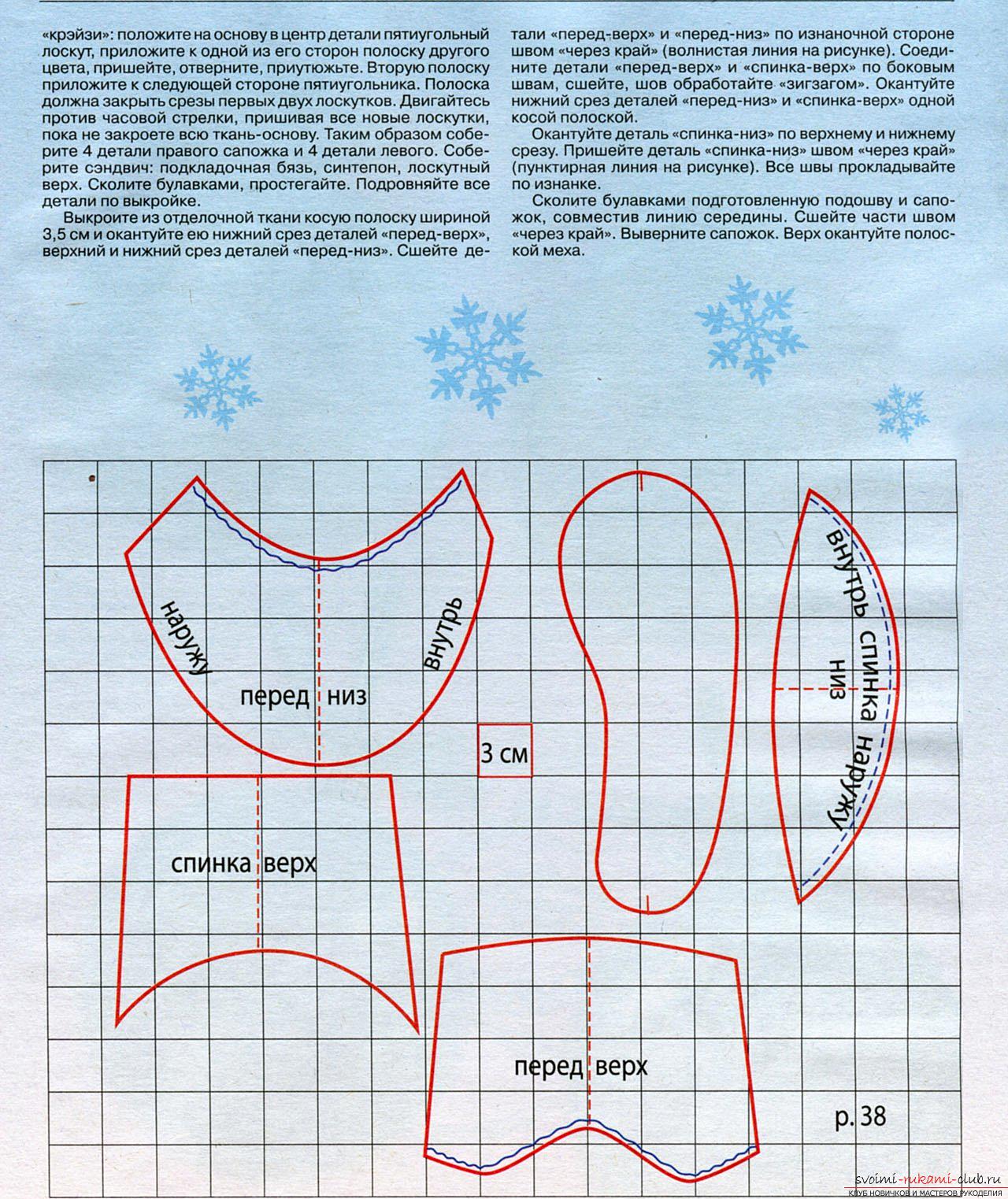

All cut edges, of course, if you haveIf this is possible, it should be done using a sewing machine. Well, try to stitch the top by hand. I recommend that you purchase an awl from a specialized store. It, in turn, will help you with sewing slippers, no matter how hard the material is. Using this tool, you can easily sew all the details. For those needlewomen who prefer notOpen slippers, but warmer ones, will be a little more difficult. I think everyone knows that making a sole pattern is absolutely not difficult. Just outline the leg around and add a few centimeters for seam allowances. Well, in order to make the top of this kind of slippers, more complex mathematical calculations are needed. Therefore, it is much easier to use the simplest wrapping method. An example for the pattern of the upper parts could be any boots or low-speed boots. Keep in mind that house shoes should not be “butt-tight”; on the contrary, they should be loose and comfortable, so that they do not cause discomfort when worn. First you need to crumple the paper. After this procedure, it will be easier to lie on the surface of the shoe. If you want your future house boots to fit completely, then use the model’s foot as a template. When you wrap, you can add folds, securing them with ordinary tape or pins. Draw the middle line and the line that connects to the sole along the front side of the boot and along the heel. Try to remove the paper without breaking the pins. Further action when creating a pattern – This is to make notches or cuts on the paper and divide the resulting template into several parts to make it easier to transfer the pattern to the fabric from which these slippers will be sewn directly. You can use the patterns that you see below. Your slippers will be warm and comfortable.

For those needlewomen who prefer notOpen slippers, but warmer ones, will be a little more difficult. I think everyone knows that making a sole pattern is absolutely not difficult. Just outline the leg around and add a few centimeters for seam allowances. Well, in order to make the top of this kind of slippers, more complex mathematical calculations are needed. Therefore, it is much easier to use the simplest wrapping method. An example for the pattern of the upper parts could be any boots or low-speed boots. Keep in mind that house shoes should not be “butt-tight”; on the contrary, they should be loose and comfortable, so that they do not cause discomfort when worn. First you need to crumple the paper. After this procedure, it will be easier to lie on the surface of the shoe. If you want your future house boots to fit completely, then use the model’s foot as a template. When you wrap, you can add folds, securing them with ordinary tape or pins. Draw the middle line and the line that connects to the sole along the front side of the boot and along the heel. Try to remove the paper without breaking the pins. Further action when creating a pattern – This is to make notches or cuts on the paper and divide the resulting template into several parts to make it easier to transfer the pattern to the fabric from which these slippers will be sewn directly. You can use the patterns that you see below. Your slippers will be warm and comfortable.

Now it's time to tell you about whatIt is better to use for sewing house slippers. You can cut out details of boots from materials such as leather, faux leather, suede, felt, cloth, etc. We should not forget about the allowances that are necessary for seams. They must be no less than 5 millimeters. Using patterns, cut out your lining. I mentioned earlier which materials are best to use. All parts must be ground separately. If you wish, you can trim the edges using braid or edging tape. Attach the top of the sneaker to the sole. The stitch should be laid along the line from toe to heel, on both sides of the slipper-boot. If the upper part of the product is larger than the sole, the remains can be used for the heel seam.

Now it's time to tell you about whatIt is better to use for sewing house slippers. You can cut out details of boots from materials such as leather, faux leather, suede, felt, cloth, etc. We should not forget about the allowances that are necessary for seams. They must be no less than 5 millimeters. Using patterns, cut out your lining. I mentioned earlier which materials are best to use. All parts must be ground separately. If you wish, you can trim the edges using braid or edging tape. Attach the top of the sneaker to the sole. The stitch should be laid along the line from toe to heel, on both sides of the slipper-boot. If the upper part of the product is larger than the sole, the remains can be used for the heel seam.