This master class will tell you how to create your own souvenirs - horse figures

A horse made of iron is created strong and gracefulstallion, which has an iridescent iron mane, and strong horseshoes. They can not help admiring! Even the master can not get rid of the idea of making him a friend-rider and a powerful cart or carriage. But, however, first thing you need to do it. And the materials for the work will go as follows:

- pipe with a width of 15 mm;

- nails of two hundred - 4 pcs .;

- in the work a small bar is used, an arbitrary piece of sheet iron and a sawn piece resembling a horse's head with a width of 10 mm;

- small carnations.

A trunk of a horse is served by a length of a pipe 8 cm long. A disc 1.2 mm wide is used.

A trunk of a horse is served by a length of a pipe 8 cm long. A disc 1.2 mm wide is used.  With the help of an iron sledgehammer, it is necessary to flatten the tube along the edges, so that the trunk has a rounded abdomen.

With the help of an iron sledgehammer, it is necessary to flatten the tube along the edges, so that the trunk has a rounded abdomen.

The mare's stallion is no longer than 4.5 cm in length. The proportions of the iron piece on the horse's head are constructed according to the volume of the trunk. It draws a contour of the head.

The mare's stallion is no longer than 4.5 cm in length. The proportions of the iron piece on the horse's head are constructed according to the volume of the trunk. It draws a contour of the head.  He then sawed and grinded the Bulgarian. The triangular cutout forms the ears of the animal.

He then sawed and grinded the Bulgarian. The triangular cutout forms the ears of the animal.  Ready-made head shape.

Ready-made head shape.  The neck of the future mustang is made of an iron bar. The length along the edges is 2.5 and 2 cm. The edges of the neck are cut at an angle for attachment to the head. The neck with the head together is not more than five centimeters.

The neck of the future mustang is made of an iron bar. The length along the edges is 2.5 and 2 cm. The edges of the neck are cut at an angle for attachment to the head. The neck with the head together is not more than five centimeters.  On the other metal piece is depicted the mane of a horse, oriented to the size of the neck.

On the other metal piece is depicted the mane of a horse, oriented to the size of the neck.  With the help of a grinder and a cutting disc, you need to make cuts that look like curls.

With the help of a grinder and a cutting disc, you need to make cuts that look like curls.  After this, you need to sample the parts to correct them if necessary.

After this, you need to sample the parts to correct them if necessary.  Similarly, the tail is made: first a sketch is made, then longitudinal cuts, located close to each other, to resemble iron hair-cuts.

Similarly, the tail is made: first a sketch is made, then longitudinal cuts, located close to each other, to resemble iron hair-cuts.

As a subtotal - fitting the details.

As a subtotal - fitting the details.  Before welding, each of them needscompletely clean with a grinder with a grinding disc of 6 mm. This is necessary to better join them to each other. Only after this, you can proceed to the next step - the welding of the head and neck.

Before welding, each of them needscompletely clean with a grinder with a grinding disc of 6 mm. This is necessary to better join them to each other. Only after this, you can proceed to the next step - the welding of the head and neck.  Then, to the welded parts, try on and add a mane.

Then, to the welded parts, try on and add a mane.

To eliminate holes along the edges of the body, a small nail is needed, which is applied and fixed by welding. Only first, the tail is brewed.

To eliminate holes along the edges of the body, a small nail is needed, which is applied and fixed by welding. Only first, the tail is brewed.  Intermediate result of the work. For convenience of the further work it is necessary to cool hot workpiece in water.

Intermediate result of the work. For convenience of the further work it is necessary to cool hot workpiece in water.  Also, the hole on the chest of the horse closes with the same length of nail.

Also, the hole on the chest of the horse closes with the same length of nail.  The most interesting and complex moment is the preparation of the legsfrom nails, because it is important to correctly make their proportions. The length of the limbs is 8 cm. To bend the nail it is necessary to clamp it in the vice, leaving the edge 3.5 cm and hitting it with a hammer.

The most interesting and complex moment is the preparation of the legsfrom nails, because it is important to correctly make their proportions. The length of the limbs is 8 cm. To bend the nail it is necessary to clamp it in the vice, leaving the edge 3.5 cm and hitting it with a hammer.  With the help of the vice, the front "legs" of the horse are welded.

With the help of the vice, the front "legs" of the horse are welded.  Absolutely also hind legs are welded. When the first soldering is done, you can brew, keeping the work in hand or putting it comfortably on the table.

Absolutely also hind legs are welded. When the first soldering is done, you can brew, keeping the work in hand or putting it comfortably on the table.

The handicraft is almost ready.

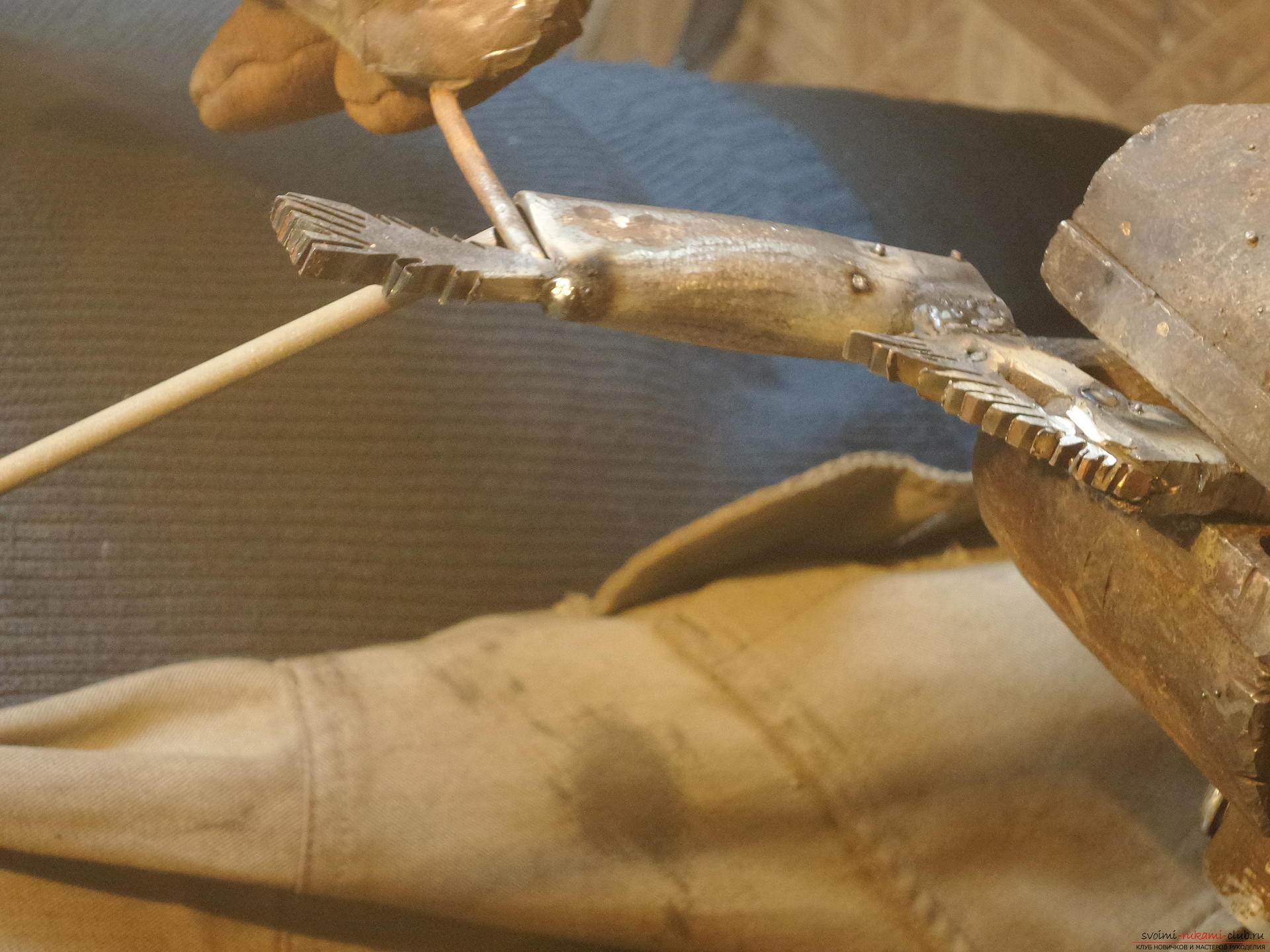

The handicraft is almost ready.  It remains to put him on his feet, bending them with pliers.

It remains to put him on his feet, bending them with pliers.

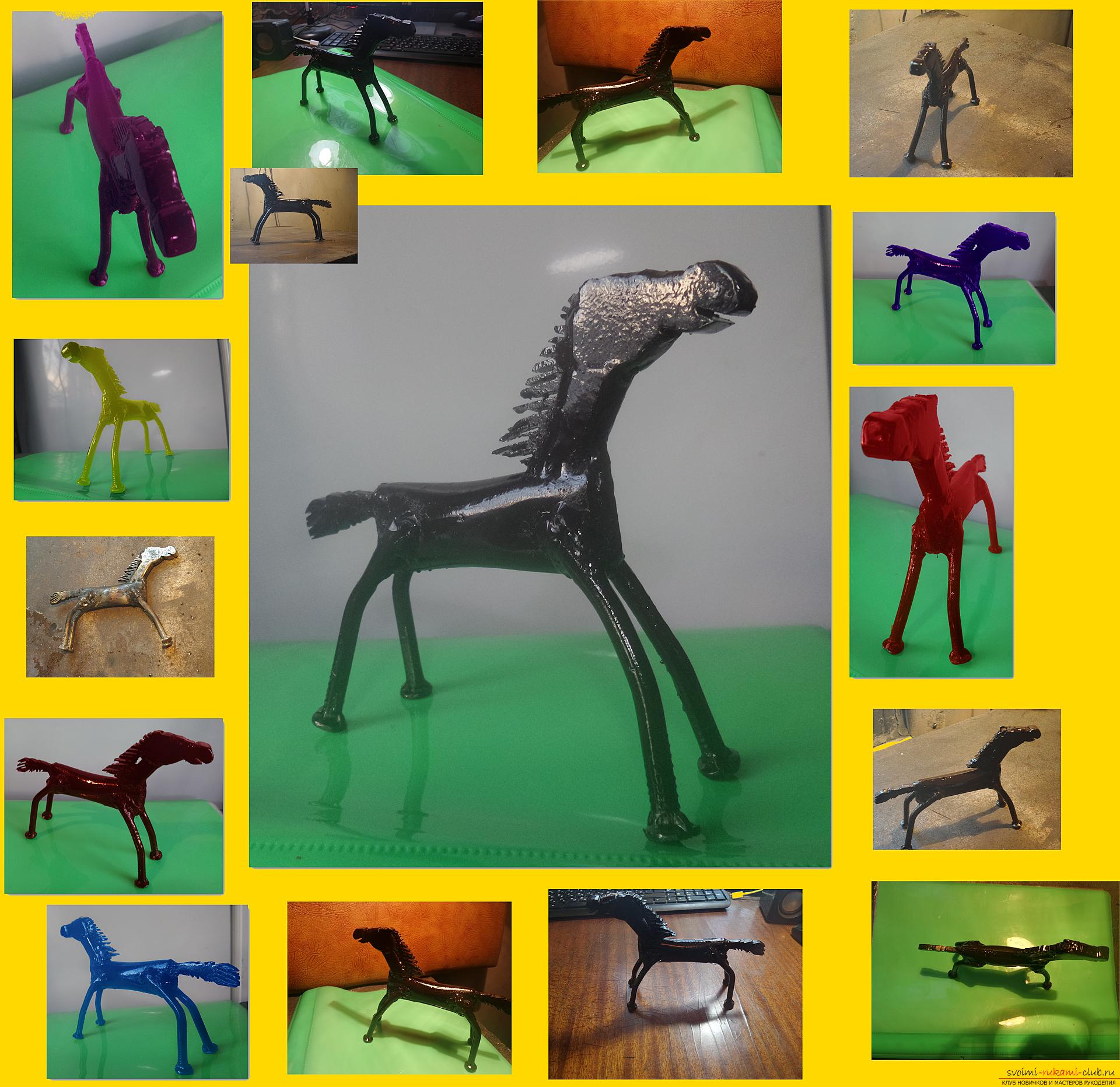

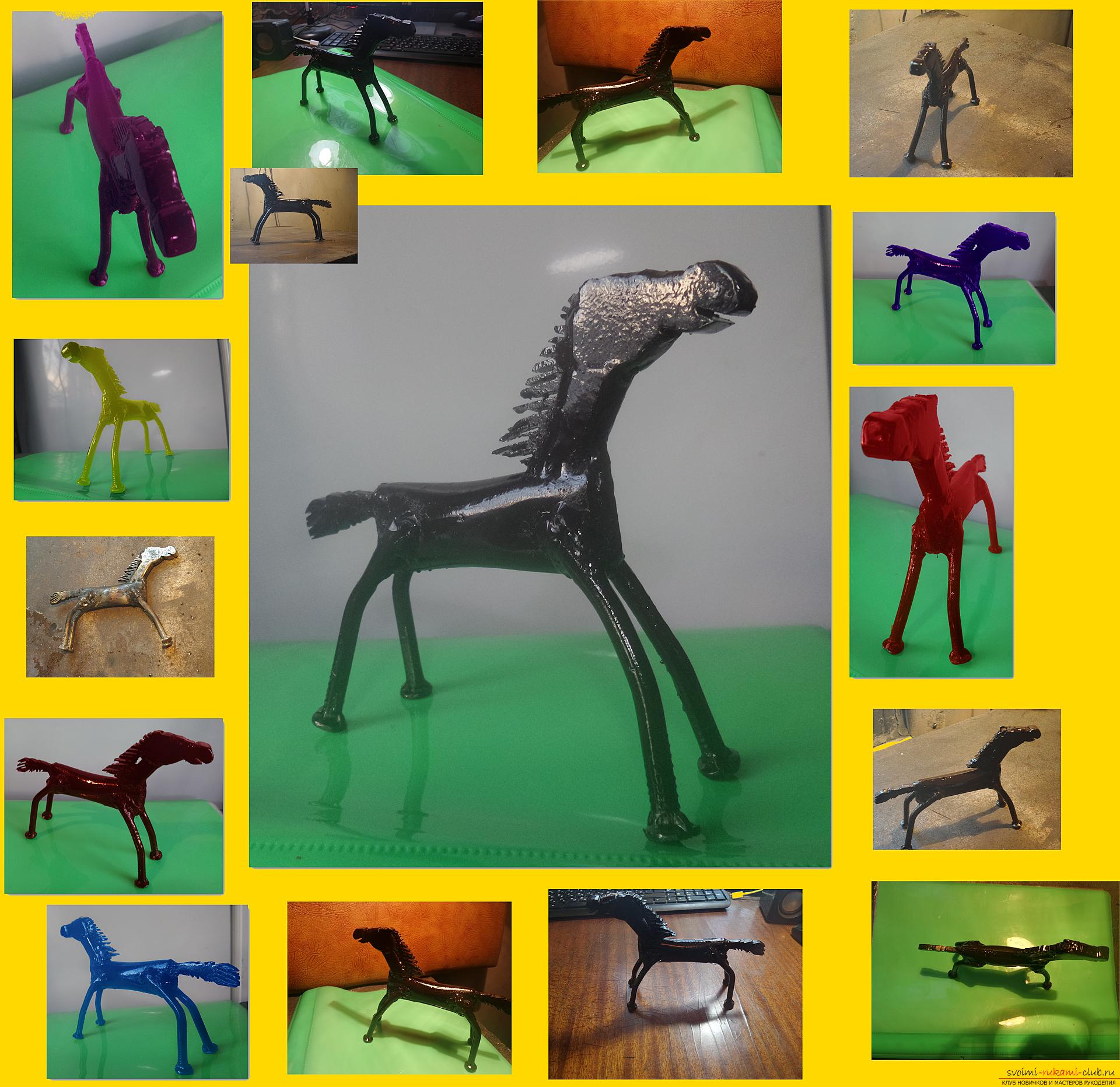

For painting the brown aerosol paint, and, maybe, any other color will do. The more interesting the result will be.

For painting the brown aerosol paint, and, maybe, any other color will do. The more interesting the result will be.  It's time to dry!

It's time to dry!  And now it's time to pose for the newborn mustang!

And now it's time to pose for the newborn mustang!